High Pressure & Temperature Metal Hose Assemblies

Global Hose & Industrial Sales Co. has brought product knowledge and experience in flexible metal hose assemblies for over 30 years. We offer a wide range of corrugated hose inner core diameters in Annular and Helical designs with multiple braiding available and engineered designed assemblies to meet your specific application needs and requirements.

Hose Protection & Materials

Corrugated Metal hoses are braided to give extra strength when the hose is pressurized and to provide a layer of protection during use. Materials such as 316L and 321 stainless steel (Hastelloy® C276 2000F/ 1093C & Inconel®625 1800F/982C. Also available in Bronze & Monel) are designed to withstand extreme variations in temperature, from cryogenic up to 1500°F (815°C). The addition of one or more braided layers helps to increase the hose working pressure and also the corrugation shape, its profile, wall thickness, and material type. Corrugated Metal hoses offer an excellent alternative for flexible and lightweight hose assemblies compared to non-metallic hose assemblies that are used in today’s market.

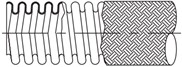

Corrugation Hose Profile

Annular Hose Profile - Independent corrugations, straight and parallel.

Helical Hose Profile - One continuous corrugation that spirals around the hose.

Standard Pressure Annular & Helical Hoses

- Size: 1/4” (6mm) up to 24” (609mm) Dia.

- Service Temp: Cryogenic service up to 1500°F (815°C).

- Pressure Rating: Full vacuum up to 4500 psig (310 bar).

High-Pressure Annular Hoses

- Size: 1/4” (6mm) up to 4” (100mm) Dia.

- Service Temp: Cryogenic service up to 1500°F (815°C).

- Pressure Rating: Full vacuum up to 5300 psig (365 bar).

Ultra-High Pressure Helical Hoses

- Size: 1/4” (6mm) up to 3” (76mm) Dia.

- Service Temp: Cryogenic service up to 1500°F (815°C).

- Pressure Rating: Full vacuum up to 12000 psig (827 bar).

Special Alloy Hoses Available

Monel®

- Size: 1/4” (6mm) up to 2” (50mm) Dia.

- Service Temp: Cryogenic service up to 800°F (427°C).

- Pressure Rating: Full vacuum up to 3025 psig (208 bar).

Inconel®

- Size: 1/4” (6mm) up to 12” (300mm) Dia.

- Service Temp: Cryogenic service up to 1800°F (982°C).

- Pressure Rating: Full vacuum up to o 2660 psig (183 bar).

Hastelloy®

- Size: 1/4” (6mm) up to 12” (300mm) Dia.

- Service Temp: Cryogenic service up to 1500°F (815°C).

- Pressure Rating: Full vacuum up to 1550 psig (106 bar).

Metal Hose Applications/Industries

- Automotive

- Bulk Material Handling

- Chemical Processing

- Oil Refining

- Petrochemical

- Power Generation

- Pulp & Paper

- Solar Power Plants

- Steam/Water

- Steel

- Utilities & Power Plants

- Water Treatment

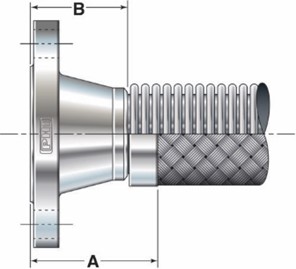

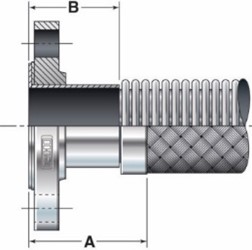

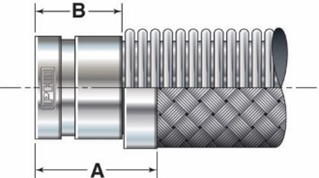

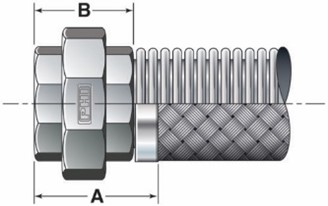

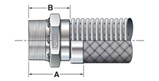

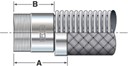

Hose End Connections/Fittings for Metal Hose Assemblies

*Additional standard and custom Hose End Connections/Fittings available upon request or per your specifications.

- A-Stub with Lap Joint Flange.

- Beveled Pipe End.

- BSPP Female Swivel.

- C-Stub with Floating Flange.

- DIN Rated Flange.

- Female Half Coupling (NPT/BSPT Threaded/Socket Weld).

- Female Swivel & Male SAE (JIC). (Female available in Straight, 45 & 90 Degree)

- Female Union (Threaded/Socket Weld).

- Floating Lap Joint w/Stub End.

- Grooved-End Fitting.

- Ground Joint Female.

- Hex Male. (NPT, BSPP & BSPT).

- Male Pipe Nipple. (NPT, BSPP & BSPT).

- Part A & Part D (Cam-Lock).

- Plate Flange.

- Raised Face Slip-On (RFSO)

- Raised Face Weld Neck flange.

- Reducer

- Tri-Clamp Sanitary Flange.

- Short & Long Radius Elbows (45° & 90°).

- Slip-On Flange.

- TTMA C-Stub Swivel.

- TTMA Flange.

- Tube End.

Custom Assemblies and Additional Services

Assemblies can be modified with a wide variety of options to meet your industries demanding requirements or special application specifications.

Assembly Protection

- Interlock Hose

- Spring Guard

- Silicone Fire Sleeve

- Heat Shrink Covering

Additional Services

- Assembly Identification

- Cleaning

- Leak and Proof Testing

- Non-Destructive Testing (NDT)

- SNT-TC-1A:

- Certification

Click here to Request A Quote or call us today at 1-888-504-2620