Flexible Corrugated Metal Hose Assemblies

Stainless Steel Flexible Corrugated Metal Hose Assemblies offers the solution where non-rigid connections for conveying liquids, gases and semi-solids are needed and offer a number of advantages including high strength, resistance to high or low temperature extremes, and corrosion resistance. It helps protect your equipment by absorbing vibrations and noise, connects misaligned rigid piping, connects moving parts of machinery or equipment, and is practical for hooking up frequently moved or dismantled equipment.

Metal hose is manufactured in three basic styles: Corrugated, Interlocked, and Square locked.

A wide range of sizes from 1/4" I.D. (inside diameter) to 24" I.D., with special sizes available upon special request.

The choice of metal hose is wide: bronze, carbon steel, stainless steel, monel, inconel, hastelloy with optional SS, or Bronze wire braid.

End fittings include male and female pipe threads, unions, flanges, flared tube fittings or other specially designed connectors.

*All assemblies are 100% tested. Special testing is available upon request: Hydrostatic, Mass Spectrometer, and Dye Penetration.

Flexible Metal Hose Assembly Features:

- Flexible corrugated hose with external braiding for high pressure capability

- Flanged, threaded, weld, and union ends available

- Tin-bronze designs for water pump connectors

- Vibration Eliminators used for absorbing vibration and noise in refrigeration and air conditioning systems

- Stainless Steel Braided Pump Connectors used for vibration absorption and the elimination of piping stress on pumps

- HVAC Heat Pump Hoses used for heat pump connections

- Quick turnaround times

- All hose assemblies leak tested

- Hydrostatic testing and certification available upon request

Type 321 Stainless Steel

- Industry standard Chromium-Nickel (18-8) to resists intergranular corrosion

- Service Range: (-320 F Cryogenic to +1500 F)

- Sizes Available: 1/4" ID thru 24" ID

Type 316 Stainless Steel

- Chromium-Nickel-Molybdenum (18-8-2) improved corrosion resistance

- Service Range: (-320 F Cryogenic to +900 F)

- Sizes Available: 1/4" ID thru 24" ID

Monel

- Nickel-Copper (73-30) Excellent corrosion resistance to Chlorine and Salt Water applications

- Service Range: (-320 F Cryogenic to +900 F)

- Sizes Available: 1/2" ID thru 3" ID

Bronze

- Copper-Tin (95-5) good general corrosion resistance used in water and steam systems

- Service Range: (-320 F Cryogenic to +400 F)

- Sizes Available: 1/4" ID thru 2" ID

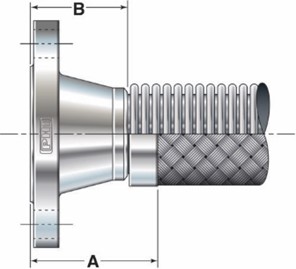

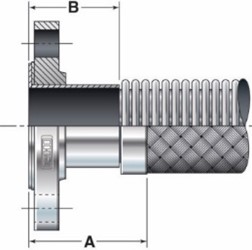

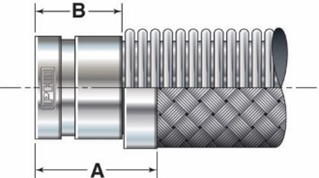

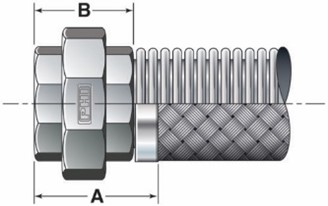

Hose End Connections/Fittings for Metal Hose Assemblies

*Additional standard and custom Hose End Connections/Fittings available upon request or per your specifications.

- A-Stub with Lap Joint Flange

- Beveled Pipe End.

- BSPP Female Swivel.

- C-Stub with Floating Flange.

- DIN Rated Flange.

- Female Half Coupling (NPT/BSPT Threaded/Socket Weld).

- Floating Lap Joint w/Stub End

- Grooved-End Fitting.

- Ground Joint Female.

- Hex Male. (NPT, BSPP & BSPT).

- Male Pipe Nipple. (NPT, BSPP & BSPT).

- Part A & Part D (Cam-Lock).

- Plate Flange.

- Raised Face Slip-On (RFSO)

- Raised Face Weld Neck flange.

- Reducer.

- Tri-Clamp Sanitary Flange.

- Short & Long Radius Elbows (45° & 90°).

- Slip-On Flange.

- TTMA C-Stub Swivel.

- TTMA Flange.

- Tube End.

Special Hose Assemblies

Large diameter metal hose are frequently the only practical transfer hose for various chemicals, particularly if elevated temperatures are included.

Applications:

With its ability to meet high demands for conveying hot and cold substances, this modern technology has the following major areas of application:

- Electrical industry and mechanical engineering: as a protective hose for electrical cables or light conductors.

- As a suction, conveying and coolant hose, e.g. when conveying and transporting liquid gas.

- Automotive industry: as an exhaust gas hose that acts as a vibration decoupler in exhaust systems.

- As a ventilation hose in technical building equipment.

- Steel industry.

- Measuring and control equipment.

- Medical equipment.

- Aviation and space travel.

- Reactor technology.

- Regenerative energies (solar heat, wind turbines, etc.)

Need even more flexibility?

Engineering can vary core widths, height and metal gauge to provide a custom hose based on your design requirements. Consult factory for details.

|

Jacketed AssemblyWhen conveyants must be maintained at a specified temperature, steam jacketing is used frequently, often in lieu of electric tracing. |

|

Guarded AssemblyUse of an external flexible armor protects metal hose from abuse due to rough handling, abrasion and bending below its limits. Often a rubber cover can accomplish this as well as armor if temperatures will permit. |

|

Lined AssemblyIf high conveyant velocities are required, use of an internal flexible metal liner will prevent damage and reduce abrasion problems. |

Click here to Request A Quote or call us today at 1-888-504-2620